Advantages and disadvantages of 12 common flanges

Advantages and disadvantages of 12 common flanges

Basic introduction to flange

Pipe flange, gasket and fastener are collectively referred to as flange joint.

1. Application:

Flange joint is a kind of component widely used in engineering design. It is an essential part of piping design, pipe fittings and valves, and also an essential component of equipment and parts (such as manhole, sight glass liquid level gauge, etc.). In addition, flange joints are often used in other specialties such as industrial furnace, thermal engineering, water supply and drainage, heating and ventilation, automatic control, etc.

2. Material:

Forged steel, WCB carbon steel, stainless steel, 316L, 316, 304L, 304, 321, chrome molybdenum steel, chrome molybdenum vanadium steel, molybdenum titanium dioxide, rubber lining, fluorine lining material.

3. Classification:

Flat welding flange, neck flange, butt welding flange, ring connection flange, socket flange, blind plate, etc.

4. Executive standard:

There are GB series (national standard), JB series (Mechanical Department), Hg series (Chemical Department), ASME B16.5 (American Standard), bs4504 (British Standard), DIN (German standard), JIS (Japanese standard).

5. International pipe flange standard system:

There are mainly two systems of international pipe flange standards.

The European pipe flange system represented by DIN (including the former Soviet Union)

American pipe flange system represented by American ANSI pipe flange.

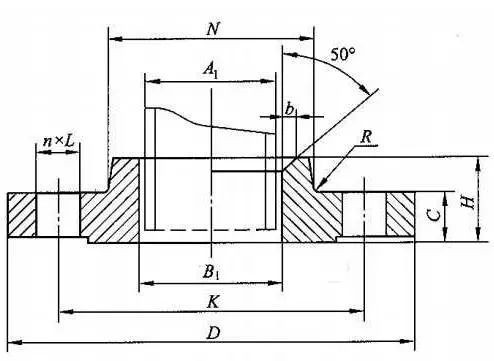

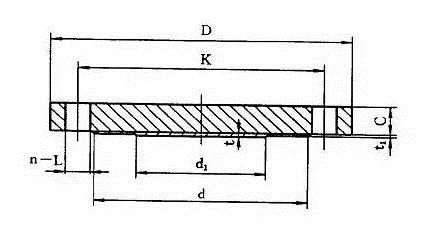

1. Plate flat welding flange

Plate type flat welding flange (chemical standard hg20592, national standard GB / t9119, mechanical JB / T81).

Advantage:

It is easy to get materials, simple to manufacture, low cost and widely used.

Disadvantages:

Due to poor rigidity, it is not allowed to be used in chemical process piping system with requirements of supply and demand, flammability, explosion and high vacuum degree, and occasions with high and extreme hazards.

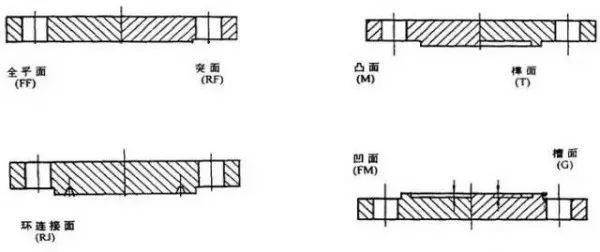

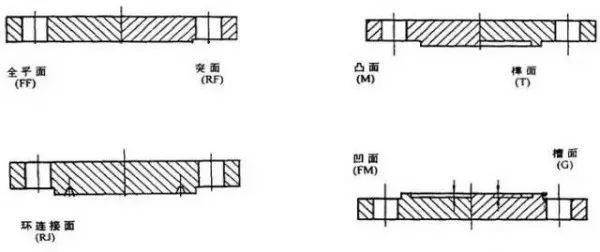

The sealing surface type has flat surface and protruding surface.

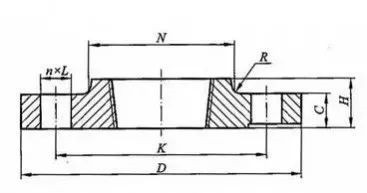

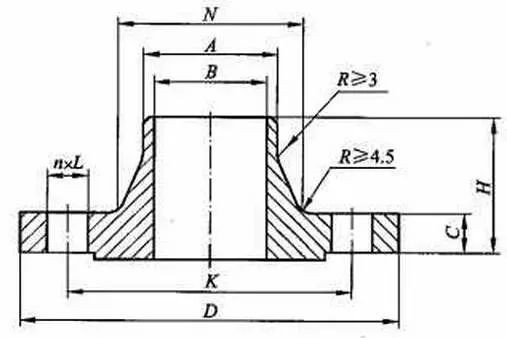

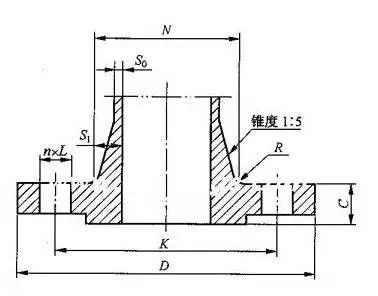

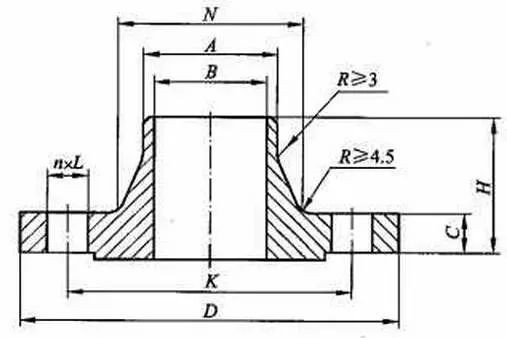

2. Neck flat welding flange

The welding flange with neck belongs to the national standard flange system, which is one of the manifestations of the national standard flange (also known as GB flange), and is one of the commonly used flanges on equipment or pipeline.

Advantage:

It is convenient to install on site, and the process of welding line rubbing can be omitted.

Disadvantages:

The neck height of the welding flange with neck is lower, which improves the rigidity and bearing capacity of the flange. Compared with the butt welding flange, the welding workload is large, the electrode consumption is high, and it can not stand high temperature and high pressure, repeated bending and temperature fluctuation.

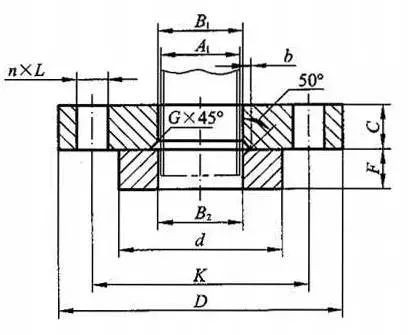

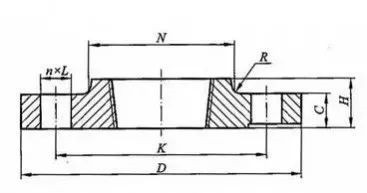

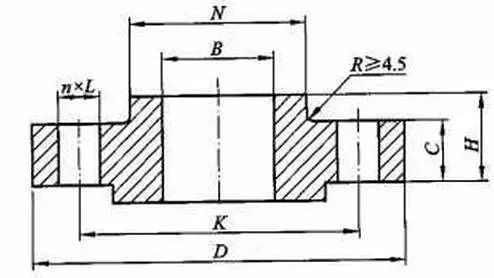

3. Neck butt welding flange

The sealing surface forms of butt welding flange with neck are as follows:

RF, FM, m, t, G, FF.

Advantage:

The connection is not easy to deform, the sealing effect is good, and it is widely used. It is suitable for pipes with large fluctuation of temperature or pressure, high temperature, high pressure and low temperature, and also for pipes conveying expensive medium, inflammable and explosive medium and toxic gas.

Disadvantages:

The welding flange with neck is bulky, bulky and expensive, so it is difficult to install and locate, so it is easier to bump during transportation.

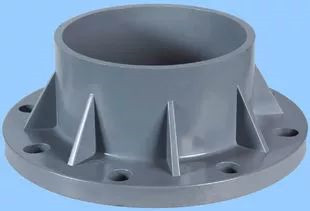

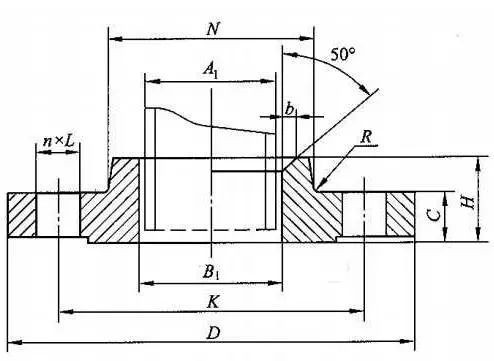

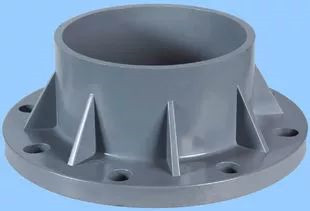

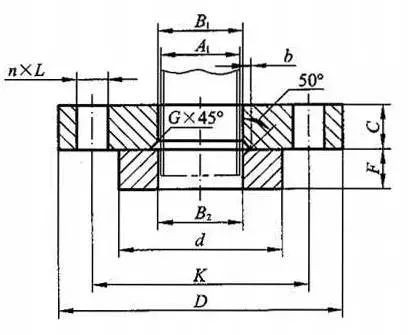

4. Integral flange

Integral flange is a kind of flange connection. It is also a kind of butt welding steel pipe flange with neck. Materials are carbon steel, stainless steel, alloy steel, etc.

In domestic standards, if is used to represent integral flange. It is mainly used in pipes with high pressure, and the production process is generally casting.

In flange type, an "if" is used to represent the type of integral flange. Generally, it is raised face (RF). If it is used in inflammable, explosive, high and extremely hazardous conditions, the sealing surface of convex concave face (MFM) and tenon groove face (TG) can be selected in addition to RF face.

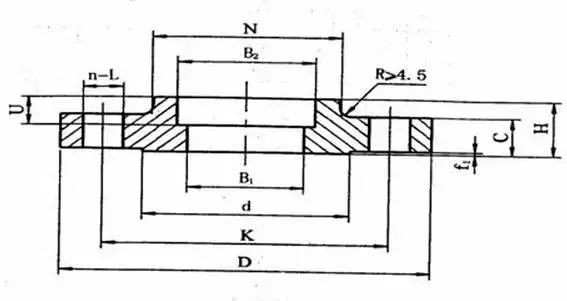

5. Socket welding flange

Socket welding flange is a flange with one end welded with steel pipe and the other end bolted.

Socket welding flange is a flange with one end welded with steel pipe and the other end bolted.

Sealing surface form:

RF, MFM, TG, RJ.

Application scope:

Boiler and pressure vessel, petroleum, chemical industry, shipbuilding, pharmacy, metallurgy, machinery, food and other industries.

It is commonly used in pipelines with PN ≤ 10.0MPa and DN ≤ 40.

6. Threaded flange

The threaded flange is a kind of non welding flange, which processes the inner hole of flange into pipe thread and realizes the connection with the pipe with thread.

Advantage:

Compared with the flat welding flange or butt welding flange, the threaded flange has the characteristics of convenient installation and maintenance, and can be used on some pipelines that are not allowed to be welded on site. The alloy steel flange has enough strength, but it is not easy to weld, or the welding performance is not good, the threaded flange can also be selected.

Disadvantages:

When the temperature of the pipeline changes rapidly or the temperature is higher than 260 ℃ and lower than - 45 ℃, it is not recommended to use threaded flange to avoid leakage.

7. Loose flange of butt welding ring

Loose flange of butt welding ring is a movable flange, which is generally matched with water supply and drainage accessories. When the manufacturer leaves the factory, there is a flange at both ends of the expansion joint, which is directly connected with the pipeline and equipment in the project by bolts.

Effect:

The purpose of loose flange with butt welding ring is generally to save materials. Its structure is divided into two parts, one end of the pipe is connected with the pipe, and the other end is made into butt welding ring. The flange plate is made of low-grade materials, while the pipe part is made of the same materials as the pipe, so as to save materials.

Advantage:

Cost saving, when the pipe material is special and expensive, the cost of welding the same material flange is high. It is not convenient for welding or processing or requires high strength, such as plastic pipe, glass steel pipe, etc. It is convenient for construction, for example, it is not convenient to align the flange bolt holes during connection or to prevent the bolt holes of equipment flange from changing in the future.

Disadvantages:

Low bearing pressure, low strength at the welding ring (especially when the thickness is less than 3mm).

8. Loose flange of flat welding ring

The loose flange plate of the flat welding ring is a movable flange plate, which is directly connected with the pipeline and equipment in the project by bolts.

The purpose of loose flange plate with flat welding ring is generally to save data. Its structure is divided into two parts, one end of the pipe is connected with the pipe, the other end is made into flanging, and the flange plate part is sleeved on flanging.

Advantage:

It is convenient for welding or processing or requires high strength, such as plastic pipe, glass steel pipe, etc.

It is convenient for construction, such as flange bolt hole corresponding to alignment during connection or to prevent change of flange bolt hole of equipment replacement in the future.

Save money when the price is high. When the pipe material is special, the cost of welding the same material flange is high.

Disadvantages:

Low acceptance pressure.

The strength of the welding ring is low (especially when the thickness is less than 3mm).

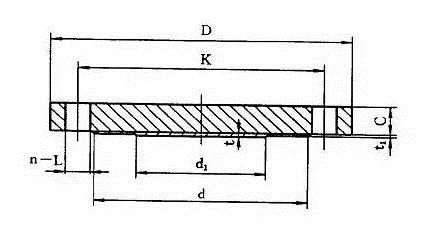

9. Flange cover

Also known as blind flange and blind plate, it is a flange without holes in the middle for sealing the pipe plug. The function is the same as welding head and screw cap, except that blind flange and screw cap can be removed at any time, while welding head is not.

Sealing surface of flange cover:

FF, RF, MFM, TG, RJ

10. Lining flange cover

The lining flange cover is a blind flange. The side close to the medium is overlaid with stainless steel as a whole. The lining flange cover is used as blind plate on the pipeline with corrosive medium. The difference between the lining flange cover and the common flange cover is that the anti-corrosion lining is added on the contact surface with the medium.

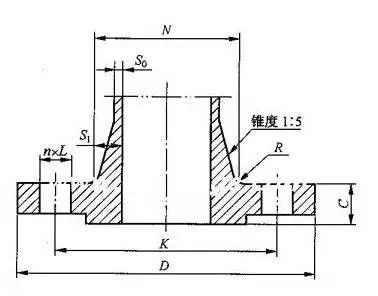

11. American standard flat welding flange with neck

The flat welding flange with neck is connected to the pipe end, which is mainly the parts connecting the pipe and the pipe. There are holes on the neck flat welding flange, and bolts can be worn to make the two flanges connected tightly, and the flange is sealed with gasket.

The gasket is placed between the two flange sealing surfaces. After the nut is tightened, the specific pressure on the gasket surface reaches a certain value, which causes deformation, and fills the uneven parts on the sealing surface, so that the connection is tight. Flange connection is a kind of detachable connection. According to the connected parts, it can be divided into vessel flange and pipe flange. The welding flange with neck is suitable for the connection of steel pipe with nominal pressure not more than 2.5MPa.

The neck flat welding flange is used for butt welding of flange and pipe. It has reasonable structure, large strength and rigidity, can withstand high temperature and high pressure, repeated bending and temperature fluctuation, and has reliable sealing performance. The neck flat welding flange with nominal pressure of 0.25-2.5mpa adopts concave convex sealing surface.

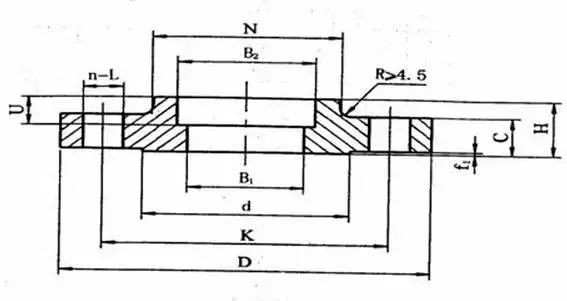

12. American standard butt welding flange

American standard flange is the part that makes the pipe and the pipe connect with each other and connect to the pipe end. American standard butt welding flange is made by forging and casting.

American standard butt welding flange can be divided into American standard butt welding flange with neck and American standard butt welding flange without neck according to the situation with neck.

American standard butt welding flange consists of two flange plates and flange gasket, which are fastened together with bolts to complete the connection. There are holes in American standard flange, bolts make two flanges connected tightly, and the flange is sealed with gasket.

Basic introduction to flange

Pipe flange, gasket and fastener are collectively referred to as flange joint.

1. Application:

Flange joint is a kind of component widely used in engineering design. It is an essential part of piping design, pipe fittings and valves, and also an essential component of equipment and parts (such as manhole, sight glass liquid level gauge, etc.). In addition, flange joints are often used in other specialties such as industrial furnace, thermal engineering, water supply and drainage, heating and ventilation, automatic control, etc.

2. Material:

Forged steel, WCB carbon steel, stainless steel, 316L, 316, 304L, 304, 321, chrome molybdenum steel, chrome molybdenum vanadium steel, molybdenum titanium dioxide, rubber lining, fluorine lining material.

3. Classification:

Flat welding flange, neck flange, butt welding flange, ring connection flange, socket flange, blind plate, etc.

4. Executive standard:

There are GB series (national standard), JB series (Mechanical Department), Hg series (Chemical Department), ASME B16.5 (American Standard), bs4504 (British Standard), DIN (German standard), JIS (Japanese standard).

5. International pipe flange standard system:

There are mainly two systems of international pipe flange standards.

The European pipe flange system represented by DIN (including the former Soviet Union)

American pipe flange system represented by American ANSI pipe flange.

12 flange types and features

1. Plate flat welding flange

Plate type flat welding flange (chemical standard hg20592, national standard GB / t9119, mechanical JB / T81).

Advantage:

It is easy to get materials, simple to manufacture, low cost and widely used.

Disadvantages:

Due to poor rigidity, it is not allowed to be used in chemical process piping system with requirements of supply and demand, flammability, explosion and high vacuum degree, and occasions with high and extreme hazards.

The sealing surface type has flat surface and protruding surface.

2. Neck flat welding flange

The welding flange with neck belongs to the national standard flange system, which is one of the manifestations of the national standard flange (also known as GB flange), and is one of the commonly used flanges on equipment or pipeline.

Advantage:

It is convenient to install on site, and the process of welding line rubbing can be omitted.

Disadvantages:

The neck height of the welding flange with neck is lower, which improves the rigidity and bearing capacity of the flange. Compared with the butt welding flange, the welding workload is large, the electrode consumption is high, and it can not stand high temperature and high pressure, repeated bending and temperature fluctuation.

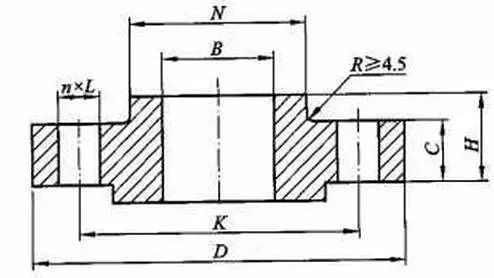

3. Neck butt welding flange

The sealing surface forms of butt welding flange with neck are as follows:

RF, FM, m, t, G, FF.

Advantage:

The connection is not easy to deform, the sealing effect is good, and it is widely used. It is suitable for pipes with large fluctuation of temperature or pressure, high temperature, high pressure and low temperature, and also for pipes conveying expensive medium, inflammable and explosive medium and toxic gas.

Disadvantages:

The welding flange with neck is bulky, bulky and expensive, so it is difficult to install and locate, so it is easier to bump during transportation.

4. Integral flange

Integral flange is a kind of flange connection. It is also a kind of butt welding steel pipe flange with neck. Materials are carbon steel, stainless steel, alloy steel, etc.

In domestic standards, if is used to represent integral flange. It is mainly used in pipes with high pressure, and the production process is generally casting.

In flange type, an "if" is used to represent the type of integral flange. Generally, it is raised face (RF). If it is used in inflammable, explosive, high and extremely hazardous conditions, the sealing surface of convex concave face (MFM) and tenon groove face (TG) can be selected in addition to RF face.

5. Socket welding flange

Sealing surface form:

RF, MFM, TG, RJ.

Application scope:

Boiler and pressure vessel, petroleum, chemical industry, shipbuilding, pharmacy, metallurgy, machinery, food and other industries.

It is commonly used in pipelines with PN ≤ 10.0MPa and DN ≤ 40.

6. Threaded flange

The threaded flange is a kind of non welding flange, which processes the inner hole of flange into pipe thread and realizes the connection with the pipe with thread.

Advantage:

Compared with the flat welding flange or butt welding flange, the threaded flange has the characteristics of convenient installation and maintenance, and can be used on some pipelines that are not allowed to be welded on site. The alloy steel flange has enough strength, but it is not easy to weld, or the welding performance is not good, the threaded flange can also be selected.

Disadvantages:

When the temperature of the pipeline changes rapidly or the temperature is higher than 260 ℃ and lower than - 45 ℃, it is not recommended to use threaded flange to avoid leakage.

7. Loose flange of butt welding ring

Loose flange of butt welding ring is a movable flange, which is generally matched with water supply and drainage accessories. When the manufacturer leaves the factory, there is a flange at both ends of the expansion joint, which is directly connected with the pipeline and equipment in the project by bolts.

Effect:

The purpose of loose flange with butt welding ring is generally to save materials. Its structure is divided into two parts, one end of the pipe is connected with the pipe, and the other end is made into butt welding ring. The flange plate is made of low-grade materials, while the pipe part is made of the same materials as the pipe, so as to save materials.

Advantage:

Cost saving, when the pipe material is special and expensive, the cost of welding the same material flange is high. It is not convenient for welding or processing or requires high strength, such as plastic pipe, glass steel pipe, etc. It is convenient for construction, for example, it is not convenient to align the flange bolt holes during connection or to prevent the bolt holes of equipment flange from changing in the future.

Disadvantages:

Low bearing pressure, low strength at the welding ring (especially when the thickness is less than 3mm).

8. Loose flange of flat welding ring

The loose flange plate of the flat welding ring is a movable flange plate, which is directly connected with the pipeline and equipment in the project by bolts.

The purpose of loose flange plate with flat welding ring is generally to save data. Its structure is divided into two parts, one end of the pipe is connected with the pipe, the other end is made into flanging, and the flange plate part is sleeved on flanging.

Advantage:

It is convenient for welding or processing or requires high strength, such as plastic pipe, glass steel pipe, etc.

It is convenient for construction, such as flange bolt hole corresponding to alignment during connection or to prevent change of flange bolt hole of equipment replacement in the future.

Save money when the price is high. When the pipe material is special, the cost of welding the same material flange is high.

Disadvantages:

Low acceptance pressure.

The strength of the welding ring is low (especially when the thickness is less than 3mm).

9. Flange cover

Also known as blind flange and blind plate, it is a flange without holes in the middle for sealing the pipe plug. The function is the same as welding head and screw cap, except that blind flange and screw cap can be removed at any time, while welding head is not.

Sealing surface of flange cover:

FF, RF, MFM, TG, RJ

10. Lining flange cover

The lining flange cover is a blind flange. The side close to the medium is overlaid with stainless steel as a whole. The lining flange cover is used as blind plate on the pipeline with corrosive medium. The difference between the lining flange cover and the common flange cover is that the anti-corrosion lining is added on the contact surface with the medium.

11. American standard flat welding flange with neck

The flat welding flange with neck is connected to the pipe end, which is mainly the parts connecting the pipe and the pipe. There are holes on the neck flat welding flange, and bolts can be worn to make the two flanges connected tightly, and the flange is sealed with gasket.

The gasket is placed between the two flange sealing surfaces. After the nut is tightened, the specific pressure on the gasket surface reaches a certain value, which causes deformation, and fills the uneven parts on the sealing surface, so that the connection is tight. Flange connection is a kind of detachable connection. According to the connected parts, it can be divided into vessel flange and pipe flange. The welding flange with neck is suitable for the connection of steel pipe with nominal pressure not more than 2.5MPa.

The neck flat welding flange is used for butt welding of flange and pipe. It has reasonable structure, large strength and rigidity, can withstand high temperature and high pressure, repeated bending and temperature fluctuation, and has reliable sealing performance. The neck flat welding flange with nominal pressure of 0.25-2.5mpa adopts concave convex sealing surface.

12. American standard butt welding flange

American standard flange is the part that makes the pipe and the pipe connect with each other and connect to the pipe end. American standard butt welding flange is made by forging and casting.

American standard butt welding flange can be divided into American standard butt welding flange with neck and American standard butt welding flange without neck according to the situation with neck.

American standard butt welding flange consists of two flange plates and flange gasket, which are fastened together with bolts to complete the connection. There are holes in American standard flange, bolts make two flanges connected tightly, and the flange is sealed with gasket.